TANK HEADS

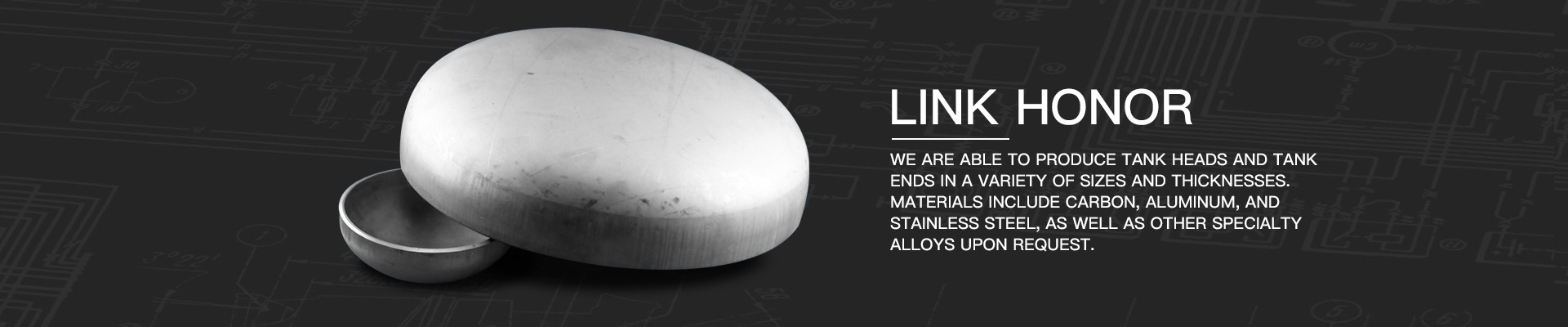

LINK HONOR is a manufacturer of dished heads for tanks and offers cold formed tank heads made from stainless steel and many other alloys.

|  |  |  |  |

LINK HONOR is a company engaged in professional manufacturing dished heads for tanks, boilers, industrial equipment.

Our customers belong to different industrial sectors: Petrochemical, chemical, pharmaceutical, cosmetic, agro-food, logistics, transports, tanks, water treatments, environment, industrial boiler, heat exchangers, etc.

We manufacture a large range of dished heads and cones to varying shapes and standards: spherical caps, flat heads, Flanged only Head, dished heads for low pressure, spherical covers, diffusion heads, cone heads, Cones for Pressure Vessels, elliptical heads 2:1(ASME), hemispherical heads, Shallow Head, Inverted Dished heads and Inverted Cones...

Custom made and/or Standard size.

We manufactures Heads according to PED 97/23 EC for pressure vessels. The stainless steel material is certificated according to Pressure Equipment Directive (97/23/EC).

We proceed according to the following manufacturing laws: CODAP, ASME, ADM.

We manufactures stainless steel tank heads, in order to avoid any pollution from other materials. This point represents another guarantee of quality for all our clients.

We produce the following caps according to national standards:

· PRC Small knuckle radius head or Shallow Head

· GRC Large knuckle radius head or Torispherical head

· Elliptical head or Semi Ellipsoidal Head

· MRC Medium knuckle radius head

· Edge machining and bevelling are made according to tnational standards.

·MANUFACTURING CYCLE OF DISHED HEADS

· Calculation of the disc’s diameter

· Disc cutting

· Disc welding, in case of disc in several parts

· Destructive or non-destructive controls (if requested in your order)

· Cap pressing process and control of the knuckle radius

· Knuckle radius forming and knuckle radius control

· Edge machining according to the customer's requests.

· Dished head control at the end of the manufacturing process

· Dished head pickling

· Dished head polishing (if requested in your order)

· Openings (if requested in your order)

· Final control before consignment.

русский

русский العربية

العربية  Español

Español Português

Português Français

Français Deutsch

Deutsch 日本の

日本の Italiano

Italiano Nederlands

Nederlands Korean

Korean Republik Indonesia

Republik Indonesia भारत गणराज्य

भारत गणराज्य